News

The work was made by Nesie Junyi Wang, a 4th year photography student at the Royal Academy of Art in The Hague. She was inspired by the flame retardant properties of Kaumera.

Kaumera takes a big step forward. Four Dutch water authorities are working together in a new cooperative responsible for production. A new startup BV takes charge of market operations. This BV, Kaumera Sales and Services BV, is owned 50/50 by Royal HaskoningDHV and the Kaumera cooperative, taking the production of this biobased raw material into a new phase. Market interest in Kaumera has been demonstrated in recent years. It is now time to accelerate the development with more capacity and focus.

Meet me

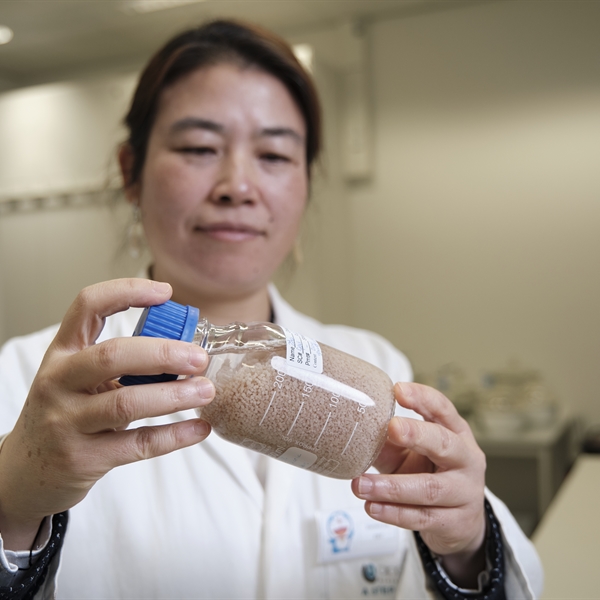

The Raw Materials Plant: high-tech developments

Raw materials are becoming scarce, so we need to think circularly and minimise waste. That is why the Dutch water authorities are working in numerous ways to transform wastewater treatment plants into 'factories' where clean water, clean energy and valuable raw materials are produced. In doing so, they contribute to a cleaner, sustainable world. A world with as little waste as possible, and with as much clean energy and reusable raw materials as possible.

My name is Kaumera

Inspire me

Creating a fully circular and bio-based building material from wastewater resources

Innovate me

Applications

A totally new raw material, never before discovered, requires innovative thinking and perseverance. This is how we arrived at the two Kaumera plants and the many possible applications for Kaumera.